Performing Yamaha spark plugs and compression maintenance on your outboard is one of the keys to its overall longevity and reliability.

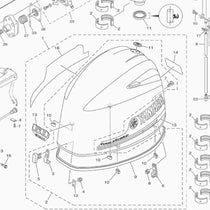

Begin this step of your Yamaha 100-hour service by removing the plastic shrouding over your spark plugs or ignition coils. Yamaha engines come from the factory with NGK brand spark plugs, and PartsVu carries a wide assortment of these OEM plugs. In most applications, the spark plugs come pre-gapped, but it is advisable to re-check gap to make sure that no plugs were damaged during manufacturing or shipment. Again, the information in your owner’s manual is helpful – or you can consult Yamaha Engine Specifications and Capacities Chart.

Yamaha Spark Plugs Inspection

As you remove the old spark plugs, keep track of which plugs come from which cylinders. Note if the plug appears to be wet from water, oil, or gasoline. Note if the plug exhibits evidence of heavy carbon deposits, other fouling, or rust – all indicative of other problems. If you were to take your engine to a dealer for 100-hour service, this is the point at which they would perform a compression test by connecting a compression gauge to the cylinders individually and using the starter motor to turn the engine over and check its ability to pressurize the cylinder. If you are going to perform this test at home, you will either need a remote starter button, or a friend who can turn the ignition key with the kill lanyard removed. This cranking with the ignition disabled will also prime the fresh oil around the block, reducing friction at startup after the service is complete. Repeat testing for all cylinders and compare results. Readings will vary from gauge to gauge, so the test is more about measuring the difference in readings with ideal results being less than a 10 percent variance.

With the compression test completed – or skipped – you can now begin installing your new spark plugs. For ease of removal and to reduce the risk of thread damage to the cylinder head, apply a drop of oil with the tip of your finger to the threads of the plug using care to avoid wetting the electrode or porcelain center of the plug. Thread the plugs into the cylinder head by hand using caution not to cross thread. NGK uses a crush washer that will press down and provide a tight seal as you tighten - full torque is between 18-21 ft. lbs. Reinstall the plug wires or coils in the same order and use a small amount of Yamaha grease for the threads of the bolts, coils and covers.

Yamaha 100-hour service Step # 1 - Oil Change

Download Free eBooks

How to Perform Yamaha 100-Hour Service eBook available for both 4-stroke and 2-stroke outboards.

What’s A Spark Plug Gap?

A spark plugs’ tip temperature and the voltage necessary to fire the plug are directly affected by the gap setting.

Most manufacturers set the gap from the factory for that plugs most popular application. Unfortunately, that plug may have hundreds of applications from automobiles to golf carts. Setting the gap for your particular engine is important as insufficient spark plug gap can cause pre-ignition, detonation and even engine damage. Too much gap can result in a higher rate of misfires, loss of power, plug fouling and poor fuel economy.

NGK spark plugs come from the factory pre-gapped and are the plugs of choice for the Yamaha spark plugs and compression step of 100-Hour maintenance.