Getting your Yamaha two-stroke outboard-powered boat ready for season requires a little more effort than just turning on the battery switch and turning the key. By following this 2-Stroke Yamaha Season Breakout Guide, you can make sure your first trip out on the boat is a safe and enjoyable one!

Uncover & Unwrap

Now that the snow has melted and you can actually see your boat again, the first step of 2-Stroke Yamaha season breakout is peeling off the covers and see how it faired through the winter. But, before you wad up the cover and put it in a trash bag, that expensive hunk of canvas is worthy of a little attention. The fabric itself should be cleaned using a soft brush and a canvas friendly cleaner like Starbrite Sail & Canvas cleaner. Inspect broken snaps and replace them as needed using a snap tool – a worthy investment for a boat owner. Remaining snaps should be lubricated with a Snap Stick – which also works really well on zippers.

Finally, consider washing the canvas while it is still installed on the boat and letting it dry thoroughly before storing it. This will help preserve its shape as it dries and make it easier to install next time.

If you happened to shrink-wrap your boat, getting that heavy tape residue off the hull side can be a challenge. BoatLIFE Life-Calk Solvent and Cleaner does a great job and will not hurt the gel coat finish. As with any chemical, wear appropriate gloves and personal protective equipment and use in a well-ventilated area. This product also does an excellent job brightening up white vinyl rub rail inserts or trailer PVC guideposts.

Walk-Around Inspection

With the cover off the boat, it’s time for a careful walk-around inspection. Do you notice any leaks under where the boat is sitting? Check specifically below the engine – which has gear lube, engine oil, trim fluid, and gasoline as possible causes for any leaks or stains found below.

What about your drain plug area? The presence of algae can indicate that your hull has been slowly dripping water for some time. Thru-hulls at and below the waterline are also very worthy of consideration. Intake grates can be crushed from beaching, trailers, forklifts, or lifting slings. Crushed intake grates will reduce water flow to the equipment they supply. Plastic thru-hull fittings can crack from age and UV exposure, and are especially dangerous for boats that float in the water all the time.

Many boaters do keep their boat in the water during the season, and for those folks, springtime is fresh bottom paint time.

2-Stroke Yamaha Season Breakout Is a Great Time to Protect Your Boat from UV Rays

Just like your body, the best time to apply sunblock is before you get burnt, so consider a coat of wax to protect your boat from UV rays too. If you noticed your hull is chalky, applying a polishing compound prior to waxing will really bring out a bright shine. Practice makes perfect, but the product is best applied using a high-speed buffer and working small sections at a time. Always apply wax after buffing. For a pro tip, wash the boat again after you’ve completed waxing. This will help knock down the static charge all that rubbing creates and will keep dust from sticking to your shiny ride.

Your fiberglass is not the only thing that faces a tough battle against UV and dirt. Upholstery can be easily damaged from exposure to the sun or harsh chemicals. Marine upholstery is generally sewn with cotton thread which can be very sensitive to bleach, and household cleaning products, like 409, will accelerate the vinyl “drying out” which leads to cracking. Your vinyl should feel soft and supple.

Resist the urge to go straight to powerful household products when you pull the cover off the boat and find mold or mildew on your vinyl. Go for a marine vinyl cleaner instead. Used correctly, these products will lift dirt and light staining without damaging the delicate vinyl. Using a soft brush, microfiber rag, and melamine foam sponge will yield the best results - especially on textured vinyl.

To keep your vinyl conditioned, protected, and looking its best, consider 303 Products Aerospace Protectant. This clear spray is as good as it gets for extending the life of your expensive upholstery.

Battery & Electrical System Assessment

With the exterior looking good, the next 2-Stroke Yamaha season breakout steps require climbing inside the boat. Many boaters remove or disconnect their batteries for storage during the offseason. Prior to reinstalling those batteries, visually inspect them for evidence of physical deformation (swelling or sucking in), leakage, corrosion, and age.

Any fluid leak or crystal accumulation on the battery should be considered as hazardous. CRC makes a battery cleaner that indicates the presence of acid and will neutralize the acidic properties. The battery should have a punch sticker indicating when it was installed but usually also has a date of manufacture or date sticker applied. These will be small round stickers that read a letter (indicating month) and number (indicating year). A sticker reading “D7” would be an April 2017 manufacture date.

Generally speaking, marine batteries will last about three years with proper care and maintenance, so consider a replacement if your battery is at or older than three years. For wet cell batteries, this is the best possible time to check and adjust fluid levels inside the battery to compensate for evaporation. Follow the manufacturer’s instructions and use protective gear as you are working with acid. Close the battery back up and charge in the shop or re-install and charge if your vessel is equipped with a marine-grade onboard charger.

A terminal brush is an inexpensive and very handy tool to help with battery installation. You can easily clean terminals and wire ends before reinstalling the leads. Once installed, the dissimilar metals used to create the ring terminals, battery cable ends, and terminal studs will promote corrosion, so a corrosion inhibitor is really important in this area.

Don’t forget to properly tighten your battery hold-downs as vibration is one of the leading causes of premature battery failure. Now that your battery is installed, it is a great time to do a systems check on your boat. Begin by toggling switches on and off and verifying the associated function turns on as it should. This is a quick and easy way to check pumps and lights before getting back on the water.

Older festoon bulbs used for navigation and anchor lights are quite susceptible to corrosion and often fail from sitting. Clean the contacts with a wire brush and consider replacing older bulbs with an LED bulb for brighter lighting that uses less amperage.

Bilge Pumps, Float Switches & Fresh Water Systems

Float switches and bilge pumps are critical safety gear that is worth the effort to check out during your 2-Stroke Yamaha season breakout. Properly wired float switches should function with or without the battery switch being turned on, so be sure to check both ways.

Most boats are also wired so that the operator can manually toggle the bilge pump on. Verify that the pump runs properly and that your bilge wiring, discharge hose, hose clamps, and thru-hull fitting are all in great shape. Keep in mind that your boat may have multiple pumps/floats. If your boat’s freshwater system was winterized, be sure to fill your tanks and flush antifreeze from the system and dispose per the manufacturer’s recommendations. Consider a product like Spring Fresh to flush the freshwater system and clean the lines of any remaining antifreeze.

2-Stroke Yamaha Season Breakout - Any Uninvited Guests?

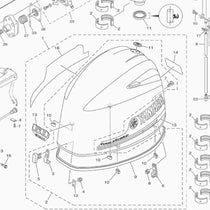

Resist the urge to turn the key and start that engine just yet. Mother nature has had months to wreak havoc on your boat, so spend a few minutes making sure you don’t have any surprises waiting. Remove your cowling and begin with a visual inspection of your engine. From birds nesting inside the cowling’s air intake to mud dauber wasps constructing condos to ants invading wiring harnesses, critters have no place inside your engine. Shine a flashlight inside your prop to the exhaust path or remove the prop to inspect that area as well if it was not taped shut for storage.

Check Engine Fluids

Once you are critter-free, the next 2-Stroke Yamaha season breakout step is to evaluate your fluids. Even if you stabilized your fuel and performed a full 100-hour service prior to the layup as Yamaha recommends, there is no telling what might have gone on in the winter months.

Pull a large fuel sample by removing your fuel supply line and pumping with the primer bulb into a clear glass container. Check for water or debris. This is also a great time to inspect your fuel supply hoses, clamps, and primer bulb for signs of cracking or wear. Replace as needed.

Reconnect your fuel supply line to the engine and pump the primer bulb until it is firm and all engine fuel cavities have been filled. Check the onboard oil tank and remote oil tank (if applicable) and note if the level appears to be significantly overfull – a possible indication that water contaminated the oil tank.

Use a flashlight illuminate the reservoir and look carefully for debris or a waterline. If you did not replace your inline oil filter during your service, now is a great time to do so. Pick up a couple of absorbent mats because there is no “clean” way to do this job. Gear lube is also worthy of an inspection at this point.

While you may have serviced and changed your lower unit lube just before your layup if you didn’t thoroughly “burp” excess air from the lower unit while filling, you may have room for more lubricant after months of sitting. It also gives you one more chance to verify that no water has contaminated the lubricant during the offseason.

2-Stroke Yamaha Season Breakout - Flush Your Engine

With your pre-checks all completed, it is time to connect a hose and move to the helm. Be sure that your flush attachments fit your lower unit appropriately, and remove the lower unit intake screens for the best water pickup. Note that Yamaha SHO engines and lower units with low water pickups in some horsepowers require additional flush block-offs to make sure they don’t suck air.

In the absence of the OEM block off, duct tape works too. If you have not previously run your engine on a flush attachment, consult your owner’s manuals for specific instructions. From the helm, lower the engine into a normal running position. Verify the garden hose water is fully flowing and the area around the boat and propeller are clear.

With the control in neutral and, key lanyard hooked up, turn the key to the “run” position. Check your gauges and observe the voltage reading. Ideally, the reading should be in the 12.6-13.2V range. If lower, charge your starting battery and further investigate. Start the engine and allow it to idle – listening for any abnormal noise or vibration. Verify that the gauges are all working properly, and the engine is charging the on-board battery between 13.6-14.3V.

Check for adequate water flow coming from the exhaust and tell-tale stream of your engine. If the engine runs properly on the hose, turn it off and visually re-inspect the engine for leaks after allowing it to sit for a few minutes. Reinstall the cowling, remove the flush (and tape) and get ready to go boating!

Hitch Up and Go, But First…

Before you hook up your truck and head to the ramp, give that trailer a good inspection too. The following are easy steps to follow:

- Test the lights - including brake lights and turn signals

- Check the inflation on your tires when the tires are cold.

- Check the tread on the tires– try sticking a penny upside down in the tread. If the top of Lincoln’s head is visible, you need new tires.

- Check the tires for cracks on the sidewalls. The DOT date code listed on the side will give you a clue as to the age of your rubber.

- If you have brakes on your trailer, check them. Drive the trailer around for a few minutes, coming to several stops. If the hubs or rotors are hot after this test drive, the brakes are working. Listen for any abnormal noises while driving the trailer.

- If your trailer has a brake battery, hook it up to a charger to make sure it’s working.

- Check and lubricate the wheel bearings.

- Check the lug nuts in a star pattern.

- Check the winch strap and tie-downs for wear. If they’re fraying or torn, it’s time to replace them. Dry rot frequently occurs creating potentially dangerous situations. When in doubt, replace.

- Clean the winch with some solvent-based cleaner and a cloth. An old toothbrush can be used on the smaller parts.

- Lubricate the winch after it’s dry. Use a brush and cover all parts with a light coat of winch grease. But, be careful to not apply lubrication to the strap or other tie-downs.

- Lubricate the tongue jack.

- Make sure your trailer hitch lock is working properly.

- Check safety chains to make sure they are intact and crisscrossed under the tongue. These are cheap and easy to replace, so discard rusty ones.

- Inspect the trailer-wiring harness and spray the contacts with dielectric grease to combat erosion.

- If you have rollers, check them for rust, breakage, or cracking.

- Make sure the bunks are tight and that the carpeting on them is not deteriorating.

- Be sure the hitch latch is securely closed. This should be easy if the ball is the same size as the coupler.

- Before each and every trip, make sure the pin securing the ball mount to the receiver is intact.

- Make sure your trailer registration is current.