Maintaining your Yamaha outboard motor’s optimal performance and longevity is not just about addressing issues as they arise; it’s about consistent and thorough visual inspections to identify and address potential problems preemptively. This comprehensive guide will walk you through the crucial aspects of conducting a visual inspection, digging into why it’s essential, how often it should be carried out, and the various elements to focus on during the inspection process.

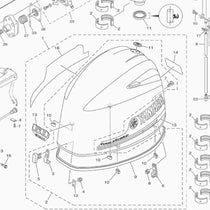

In the video embedded within this article, the visual inspection was performed on a Yamaha F250 outboard. However, the video and the step-by-step instructions included within this article apply to:

- F225 4.2L V6

- F250 4.2L V6

- F300 4.2L V6

5 Reasons It’s Important to Inspect Your Yamaha Outboard Visually

Regular visual checks are crucial to the lifespan and optimal performance of your Yamaha outboard motor. This crucial routine task aids in early problem detection prolongs the motor’s lifespan, guarantees optimal performance, upholds safety standards, and facilitates timely repairs and replacements, safeguarding your investment and ensuring seamless operation.

1. Early Detection of Issues:

Regular visual inspections of your Yamaha outboard motor allow you to spot potential problems early on, such as oil leaks, worn-out belts, or damaged anodes. Catching these issues at the onset helps prevent more significant, costlier issues down the line, ensuring your motor remains in optimal condition.

2. Prolonging the Motor’s Lifespan:

Regular inspections ensure every part of the outboard motor is in good condition. This diligent oversight helps minimize premature wear and tear, extending the motor’s life. With a longer lifespan, your Yamaha outboard motor continues to serve your boating needs reliably over the years.

3. Ensuring Optimal Performance:

Maintain the peak efficiency and performance of the outboard motor through consistent visual inspections. This attention to detail contributes to smoother operations, better fuel efficiency, and enhanced functionality, giving you an unrivaled boating experience every time.

4. Maintaining Safety Standards:

By regularly inspecting all components to ensure they are secure and functioning correctly, you uphold high safety standards for your Yamaha outboard motor operation. This practice minimizes the risk of accidents or injuries due to malfunctioning parts, guaranteeing a safer boating environment for you and your passengers.

5. Facilitating Timely Repairs and Replacements:

Regular visual inspections enable the prompt identification of necessary repairs and part replacements. This proactive approach helps avoid the compounding of issues and prevents expensive and comprehensive repairs in the future.

How Often Should You Perform a Visual Inspection of Your Outboard Motor?

The frequency of visual inspections for your Yamaha outboard motor largely depends on usage and environmental factors. As a general guideline, a comprehensive visual inspection should be performed at least twice a year before any major outings or after prolonged storage. Regular use in harsh saltwater conditions may necessitate more frequent checks to monitor and mitigate corrosion and salt buildup. Always refer to your Yamaha outboard motor’s manual for specific inspection and maintenance schedules, ensuring your engine receives the attentive care it needs for uninterrupted and optimal operation.

Step-by-Step Process for Visual Inspection of a Yamaha Outboard Motor:

1. Check the Inside Pan:

After you remove the cowling, start by checking the inside pan of the Yamaha outboard motor. Ensure there’s no oil buildup or water inside the pockets, which could indicate potential issues. A thorough visual inspection inside the pan is essential for spotting oil or salt buildup early on, helping to prevent more significant problems down the line. Use a flashlight for a clear view deep inside the pan.

2. Inspect the Interior:

Perform a visual inspection of the interior. Look for signs of dirt, damage, or wear and tear. A clean and well-maintained interior is crucial for optimal performance and longevity. Ensure all parts are secure, and if anything is damaged or missing, replace it with OEM Yamaha motor parts to preserve factory performance.

3. Examine the Belts:

Lift and visually inspect the belts. They should be in good condition and adequately tight. Yamaha recommends checking the belts every 500 hours to ensure they are not worn out or loose. Test the belt tension by twisting it; it should not turn too easily. Proper belt tension ensures the engine operates smoothly without slipping or overheating.

4. Check for Oil Leaks:

Inspect the area underneath the cam seals for any oil leakage. The presence of oil here might indicate a leak in the seals, which should be addressed immediately to prevent further damage and ensure efficient engine operation. Clean the area thoroughly and monitor for any new oil traces.

5. Inspect the Bottom Seals:

Trim up the motor and carefully inspect the bottom seals. Make sure they are not collecting or dripping oil, which can be an early indicator of seal damage or wear. Properly functioning seals prevent oil leaks and protect the motor’s internal components, ensuring reliable and smooth operation.

6. Examine Anodes:

Check the condition of the anodes, ensuring they are not crusty. Anodes in poor condition should be replaced promptly to prevent corrosion. Regular inspection and maintenance of anodes are essential for keeping the motor in the best shape possible.

7. Check the Prop Shaft:

Spin the prop and ensure the dowel in the center is not wobbling. A stable and non-wobbling dowel ensures the effective operation of the propeller and contributes to the motor’s overall performance. Address any issues with the prop shaft immediately to ensure safe and efficient motor operation.

8. Consider Further Service:

If the visual inspection indicates a need for further attention, plan for additional maintenance. Schedule services like changing water pumps, checking thermostats, and changing anodes as needed. Regular and timely maintenance will keep the outboard motor performing efficiently and prolong its lifespan.

In Conclusion: Safeguarding Your Yamaha Outboard Motor

In sum, the visual inspection of your Yamaha outboard motor is critical for long-lasting functionality and safety. Regular, thorough examinations allow you to uncover and address minor issues before they escalate into major problems, ensuring the motor operates at its peak efficiency. This habit of consistent oversight protects your valuable investment and enhances the quality and enjoyment of your boating experience.

Important Note

Always consult your engine’s owner’s manual for instructions and information specific to your engine. If you need clarification on performing an oil change, consult a Yamaha-certified mechanic.

PartsVu and Platinum Mobile Marine Partnership

Huge thanks to Frank Cutri, the owner and operator of Platinum Mobile Marine, a mobile mechanic service serving the Lee County, Florida, area, for partnering with PartsVu on the Boat Maintenance Matters series.

Together, we are working hard to build a library of step-by-step instructions on common outboard motor repair and maintenance tasks.