Maintaining a Yamaha outboard motor involves crucial steps to ensure longevity and performance. Among these, the care and replacement of external anodes stand out as a vital maintenance task. This guide delves into what external anodes are, their importance in combating corrosion, and practical tips for their inspection.

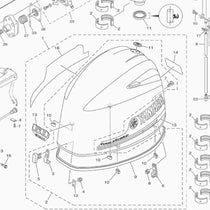

In the video embedded within this article, the external anode replacement was performed on a Yamaha F200 outboard. However, the video and the step-by-step instructions included within this article apply to:

- F150

- F175

- F200

What Are External Anodes?

External anodes are crucial components attached to outboard motors and boats to prevent corrosion. These sacrificial pieces, often made from metals like zinc, aluminum, or magnesium, are designed to corrode instead of the motor's more vital metal parts. By attracting corrosive elements in the water, external anodes protect the engine and other metal parts, extending the life of the outboard motor. Understanding the function and maintenance of these anodes is essential for any boat owner looking to safeguard their investment.

What You’ll Need for the Job

- Yamaha Outboard Anodes

- Wrench or Socket Set

- Screwdrivers

- Wire Brush or Sandpaper

Understanding Corrosion and Its Impact on Your Boat

Corrosion is the gradual destruction of materials, usually metals, by chemical and electrochemical reactions with their environment. In boats and outboard motors, corrosion can significantly damage the hull, engine, and other metal components, especially in saltwater environments. This deterioration compromises the boat's structural integrity and performance and leads to costly repairs and replacements.

Corrosion occurs in various forms, such as galvanic, electrolytic, and environmental, each posing a unique threat to marine vessels. Recognizing and mitigating corrosion through proper maintenance, including the use of external anodes, is essential for preserving your boat's longevity and functionality.

How Yamaha External Anodes Protect Against Corrosion

External anodes protect against corrosion through a process called galvanic protection. They are made from more electrochemically active metals than the boat's hull or motor components. When attached to the boat, these anodes preferentially corrode or "sacrifice" themselves, thereby preventing the less active metals on the boat from corroding. This protective mechanism is especially crucial in saltwater, where the risk of galvanic corrosion is higher due to the water's conductivity. By regularly inspecting and replacing these anodes before they are entirely eroded, boat owners can significantly extend the life of their vessels and outboard motors.

Why Are External Anodes Crucial for Your Yamaha Outboard?

External anodes play a vital role in maintaining the health and longevity of Yamaha outboard motors. Their importance cannot be overstated:

- Prevent Corrosion: They protect the metal parts of the outboard from corrosive saltwater and freshwater environments by sacrificing themselves.

- Cost-Effective Maintenance: Replacing anodes is a cost-effective way to prevent more significant expenses associated with repairing or replacing corroded parts.

- Enhanced Performance: Anodes help maintain the outboard's optimal performance and efficiency by preventing corrosion.

- Longevity of the Motor: Regular replacement of anodes extends the lifespan of the outboard motor.

- Safety: They ensure the structural integrity of the outboard motor, contributing to the boat's and its occupants' overall safety.

In summary, external anodes are a small but crucial investment in your Yamaha outboard's performance, safety, and durability.

Monitoring Anode Wear and Performance

Keeping an eye on the condition and effectiveness of your anodes is critical to ensuring the long-term health of your boat's outboard motor. When inspecting, thoroughly check all anodes, including the bracket anode, trim tab anodes, and motor anode, to ensure comprehensive protection against corrosion. Here's how to monitor anode wear and performance effectively:

- Visual Inspection: Regularly inspect the anodes for signs of significant wear or erosion. If an anode is more than 50% depleted, it's time to replace it.

- Check for Uneven Wear: Uneven wear can indicate improper installation or electrical issues with the boat that may require further investigation.

- Measure Performance: Pay attention to how quickly anodes are wearing. Rapid wear could signify an electrical problem or that the anode type isn't suitable for the water conditions.

- Assess Overall Boat Condition: Look for signs of corrosion on metal parts of the boat and outboard motor. If corrosion is present despite having anodes, it might indicate that the anodes are not performing adequately.

- Record Changes: Keep a log of anode replacements and inspections. This record can help you predict when future maintenance will be needed and identify any recurring issues.

By monitoring your anodes' wear and performance, you can make informed decisions on their maintenance, ensuring your Yamaha outboard remains in top condition.

Anode Maintenance Schedule and Tips

Maintaining the anodes on your Yamaha outboard is essential for preventing corrosion and ensuring the longevity of your motor. Here’s a basic schedule and some tips for anode maintenance:

- Regular Inspections: Check your anodes at least once every three months or more frequently if you use your boat in saltwater or brackish water.

- Seasonal Maintenance: Inspect your anodes before and after the boating season as part of your regular maintenance routine. Replace any that are significantly worn.

- Cleaning: When inspecting the anodes, clean them of any marine growth or debris to accurately assess their condition.

- Tight Connections: Ensure the anodes are securely attached and have good electrical contact with the metal parts they protect.

- Professional Advice: When in doubt, consult a marine maintenance professional to get advice tailored to your boating conditions and needs.

By adhering to this schedule and following these tips, you can effectively protect your Yamaha outboard from the damaging effects of corrosion.

Wrapping Up: The Value of Regular DIY Maintenance

Regular DIY anode maintenance is a cornerstone of responsible boat ownership. This proactive approach offers numerous benefits that extend far beyond the immediate cost savings on professional servicing:

- Prolonged Lifespan: Regular maintenance ensures that your Yamaha outboard and other marine equipment remain in optimal condition, significantly extending their useful life.

- Cost Efficiency: By performing routine checks and replacements yourself, you can avoid the high costs associated with major repairs or replacements that might arise from neglect.

- Enhanced Performance: Regularly maintaining your boat and outboard motor in top shape ensures they perform efficiently and reliably on the water.

- Safety: Regular maintenance checks can help identify and rectify potential safety hazards before they pose a risk to you and your passengers.

- Personal Satisfaction: A unique sense of satisfaction and confidence comes from knowing your vessel's ins and outs and maintaining its condition personally.

In conclusion, the value of regular DIY maintenance, particularly in managing external anodes, cannot be overstated. It's about more than just upkeep; it's about ensuring your beloved Yamaha outboard motor and boat's longevity, safety, and peak performance.

**Important Note**

Always consult your engine’s owner’s manual for instructions and information specific to your engine. If you need clarification on anode maintenance, consult a Yamaha-certified mechanic.

PartsVu and Platinum Mobile Marine Partnership

Huge thanks go to Frank Cutri, the owner and operator of Platinum Mobile Marine, a mobile mechanic service serving the Lee County, Florida area, for partnering with PartsVu on the Boat Maintenance Matters series.

Together, we are working hard to build a library of step-by-step instructions on common outboard motor repair and maintenance tasks.