If you’re having Yamaha or Mercury outboard fuel pump problems, you’re no doubt feeling frustrated. Maybe your engine is sputtering and dying while you’re trying to enjoy a day on the water, or you’re burning through your fuel faster than ever. Either way, the symptoms of a bad fuel pump on an outboard motor can be a headache you didn’t see coming, and now you need to know how to tell if your outboard motor fuel pump is bad.

Now for some good news: If you’re wondering how to test your fuel pump, troubleshooting the system can take less than 30 minutes with minimal cost to repair.

What are the symptoms of a bad fuel pump on an outboard motor?

Silence

When you try to start your engine, you should be able to hear the sound of the fuel pump engaging. If that familiar sound can’t be heard, there’s a chance it could be due to issues with the battery. Check the battery first, and depending on other symptoms you may be experiencing, it could be a good idea to troubleshoot other systems with one of our handy guides. Still, if you’re missing that motorized sound, that’s a strong sign that the fuel pump may be having issues.

Slowing, Stopping, or Sputtering

Another common symptom of a bad fuel pump is sputtering or misfiring. If you’re experiencing a bumpy ride (or possibly losing speed altogether), it could also be a sign of a clogged fuel filter that won’t allow a consistent flow. You’ll want to check the entire fuel system to ensure that any clogs and blockages in the system are addressed. We outline what parts of the fuel system you need to check in our Yamaha and Mercury troubleshooting guides

Gas Guzzling

Rapid fuel use is usually a sign that the condition of the fuel pump has deteriorated significantly. It’s a good idea to have an idea of how long a tank of gas will last you. If you notice that your tank is emptying faster than usual, it’s time to check out your fuel system before more problems take hold.

Heat

If the temperature on your gauge is on the rise, it could very well be a sign of a failing fuel pump. Keeping in mind that it may be indicative of other problems, it could be reason enough to check out your fuel system for potential issues.

If you are experiencing any combination of these symptoms, these are signs that your fuel pump is going out.

Performing Fuel Pump Tests

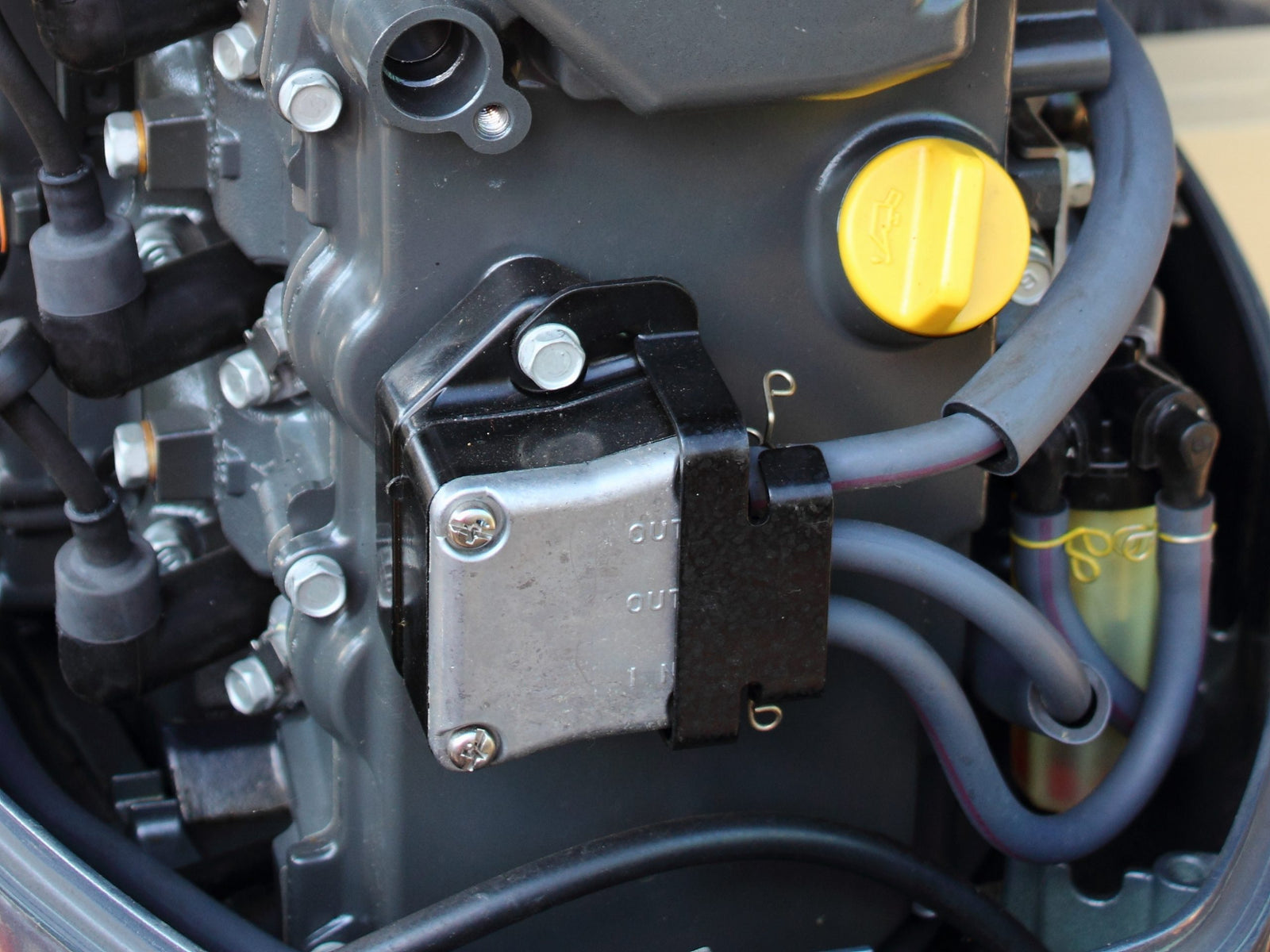

How do you test a fuel pump on an outboard motor? Fortunately, there are simple ways to test your fuel pump. This process assumes that you have already checked the rest of the fuel system for cracks, leaks, and general signs of wear to ensure continuity between the fuel tank and pump. You can check this by pumping the primer bulb until it feels hard. Fuel should travel easily from the tank all the way to the pump. Your outboard fuel filter, located just before the fuel pump, should be full.

- With the engine off and the cowl cover removed, remove the spark plug wire boot and remove the plug

- Attach the compression gauge to the spark plug hole. Then, twist the throttle position wide open and either pull the rope start or turn the starter over several times.

- The proper PSI will vary based on the engine, but in general a low PSI (under 30) means that there is a compression issue that is preventing the fuel pump from working. If you have adequate pressure, this is indicative of a bad fuel pump.

The two parts of the fuel pump that are most commonly the source of problems are the diaphragm and the one-way valves. To test them, it will be easiest to remove the pump from the engine.

One-Way Valves

The one-way valves are how the fuel is delivered to the carburetor. They allow fuel to pass from the tank in, as the name implies, only one direction. This allows enough pressure to build to force a continuous flow. If the valves aren’t closing properly, they will allow fuel to pass in either direction, which may be why your outboard is not getting fuel.

There are two valves to consider here: the inlet and the outlet. Each pump has at least one of each, but note that yours may have two outs.

The inlet accepts the flow of fuel and will often be marked with an arrow pointing inward towards the center of the pump. The outlet moves the fuel to the rest of the system and may be indicated by an arrow pointing outward. To test their functionality, you’ll need a pressure gauge.

- Remove the fuel pump

- Attach the pressure gauge hose to the outlet

- Seal the inlet firmly with your thumb

- Pump the pressure gauge a few times

- Release your thumb.

If the pressure releases, it’s a clear sign that the inlet is allowing pressure to escape in either direction and the valves aren’t in proper working condition.

Diaphragm

If the pressure does not release, and your fuel pump has a diaphragm, this is what you’ll check next. The diaphragm is an internal rubber part that pushes the fuel through the pump that is generally found only in mechanical fuel pumps. You can usually see a part of the diaphragm through a small hole on the back of the pump.

Some signs of damage are leaking, stalling, or fuel bubbling in the water. To test it, you’ll need two 10-24 bolts, four washers, and a hose clamp.

- Clamp and tighten the pump using the bolts and washers. The bolts will go through the holes used to attach the fuel pump to the engine, with washers on either end. The purpose of this is to maximize pressure.

- Attach the fuel line to the inlet

- Attach another fuel line to the outlet and clamp it off tightly.

- Prime the bulb, and keep an eye on that hole in the back of the pump. If fuel is visibly leaking through it, your diaphragm is bad.

Fuel pumps can easily be repaired using the proper fuel pump repair kit, or replaced altogether at very little cost.

How do you prevent outboard motor fuel pump problems?

Before you ever find yourself Googling how to tell if your fuel pump is bad, it may be beneficial to take some preventative measures. Fortunately, preventing future headaches isn’t hard.

Routine Maintenance

First and foremost, be sure that you’re performing the required engine maintenance at the recommended intervals. Our guides to engine maintenance for Yamaha and Mercury outboards provide a basic checklist for this process, including all the parts that each manufacturer recommends you check for cracks, leaks, or other signs of damage and wear.

Generally, fuel pumps themselves should be replaced as needed, but Yamaha specifically recommends that outboard fuel pumps should be replaced every 3 years.

With regular maintenance, the proper kit for your Yamaha or Mercury model, and the right set of tools, most outboard issues are fully preventable. Still, there are a few specific ways to keep your outboard motor’s fuel system in top shape.

Fuel Stabilizers

Another option for supporting the longevity of your motor is fuel stabilizers. Fuel stabilizers will keep fuel from going bad, remove carbon deposits, and protect the system as a whole during storage months.

In addition, fuel additives are necessary because ethanol gasoline is less than ideal for marine environments. Normal boating activity allows for more opportunity for the fuel to be exposed to water droplets, which bind to ethanol and forms a sludge-like material that is heavier than the remaining gasoline. It then sinks to the bottom of the fuel tank. When the fuel system picks this up, it can lead to clogs throughout. Preventing this with fuel stabilizers can help keep your engine healthy for far longer.

All of the products needed to maintain and protect your fuel system (and everything else) can be found at Partsvu.com.